2025 How to Choose the Best Vertical Packaging Machine for Your Business

Choosing the right equipment for your business can significantly impact productivity and efficiency, especially in the packaging sector. Among the various options available, a vertical packaging machine stands out as a versatile and effective solution for businesses looking to streamline their packaging processes. Vertical packaging machines are designed to automate the packaging of products such as granules, powders, and liquids, making them an essential tool for many industries, from food and beverage to pharmaceuticals.

When considering the purchase of a vertical packaging machine, it is crucial to evaluate several factors that will determine its suitability for your specific needs. This includes parameters such as production speed, bag size and shape, ease of use, and integration capabilities with existing systems. Understanding these elements will help you make an informed decision that not only enhances your packaging efficiency but also aligns with your overall business goals. In this guide, we will explore key considerations for selecting the best vertical packaging machine tailored to your unique operational requirements.

Understanding Vertical Packaging Machines and Their Applications

Vertical packaging machines are essential tools in various industries, renowned for their ability to efficiently package products in a space-saving manner. These machines utilize a vertical design that allows for a continuous flow of material, making them ideal for packaging items such as granules, powders, and liquids. According to a 2023 industry report by MarketsandMarkets, the vertical packaging machine market is projected to experience a significant growth rate of over 5% through 2025, largely driven by the demand for automation and increased packaging efficiency in food and beverage sectors.

When selecting the right vertical packaging machine for your business, it is crucial to consider the specific applications for which you will use the equipment. Different models are designed to handle various product sizes and weights, and understanding these parameters can significantly affect production output. For instance, certain machines are equipped with advanced sealing technologies that provide better preservation for sensitive products. Tips for choosing the best machine include analyzing your product’s nature and dimensions, assessing production speed requirements, and ensuring compatibility with existing production lines.

Additionally, it is important to evaluate the machine's maintenance and operational costs, as these factors directly impact your overall investment. Regular servicing and the availability of spare parts are essential for minimizing downtime. Tips for maintaining optimal machine performance include establishing a routine maintenance schedule and training staff on best operational practices. By understanding the specific applications and requirements for vertical packaging machines, businesses can make informed decisions that enhance their productivity and efficiency.

Key Factors to Consider When Choosing a Vertical Packaging Machine

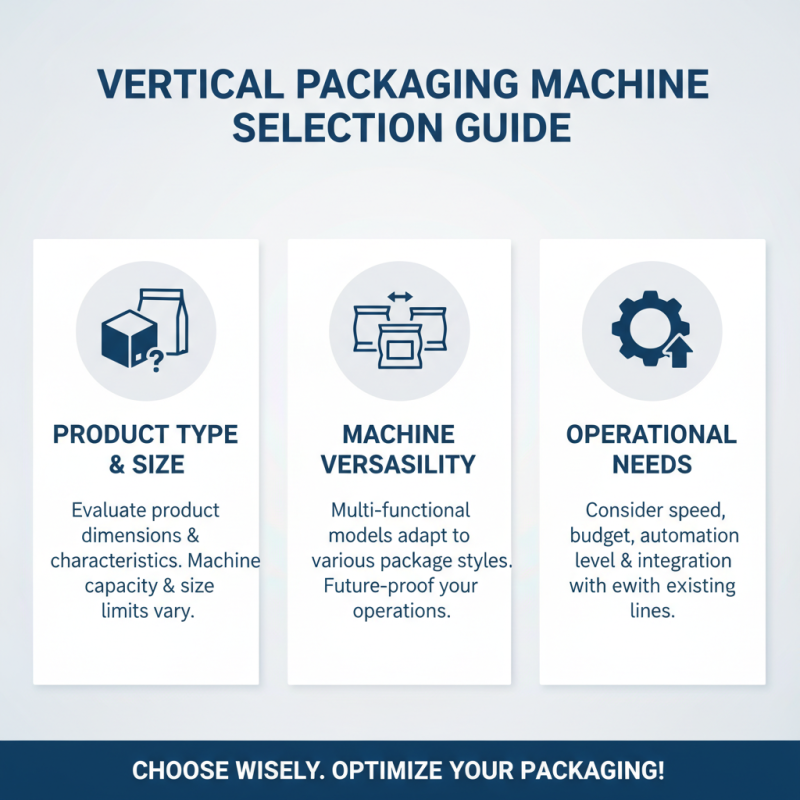

When selecting a vertical packaging machine for your business, it's essential to consider several key factors that align with your operational needs. First, evaluate the type and size of the products you plan to package. Different machines have varying capacity and size limitations, so understanding your product specifications ensures a proper fit. Additionally, consider the machine’s versatility; a multi-functional model can adapt to various package styles, such as pouches or sachets, which can be beneficial if your product line expands.

Another critical factor is the speed and efficiency of the machine. Assessing your production volume will help determine the necessary output rate and ensure that the machine can keep up with your business demands without causing delays. It's also wise to explore aspects such as ease of operation, maintenance requirements, and the availability of spare parts. A user-friendly design not only eases the training process for your staff but also minimizes downtime, which is essential for maintaining productivity in a fast-paced environment. Lastly, consider the technology and automation features offered by the machine, as these can significantly impact the overall efficiency and quality of your packaging operations.

Evaluating Your Business Needs for Packaging Efficiency

When selecting a vertical packaging machine, it is crucial to start by evaluating your specific business needs. Consider the type of products you will be packaging, as this directly influences the machine's design and functionality. Assess the size, shape, and material of your products, as well as their required shelf life. For instance, delicate items may require machines that offer more gentle handling, while products with longer shelf lives might need vacuum packaging capabilities. Identifying these parameters will help you narrow down the options to find a machine that aligns with your operational requirements.

Additionally, analyzing your production volume and speed is essential for determining the appropriate packaging solution. A high-volume production line may demand a machine that can operate at faster speeds without compromising packaging quality. Conversely, a smaller operation might prioritize flexibility and adaptability over speed. It’s beneficial to consider not only the current demands of your business but also potential growth and changes in product offerings. This foresight will help you invest in a machine that is scalable and capable of meeting future needs effectively, ensuring both efficiency and cost-effectiveness in your packaging operations.

2025 Vertical Packaging Machine Efficiency Evaluation

Comparing Different Types of Vertical Packaging Machines

When choosing the best vertical packaging machine for your business, it is essential to compare the various types available in the market. Vertical Form Fill Seal (VFFS) machines are among the most popular due to their efficiency and versatility. According to a recent industry report, the global vertical packaging machine market is expected to grow at a CAGR of 4.5% between 2023 and 2028, driven by increasing demand for packaged food and consumer goods. VFFS machines can handle a wide range of products, from granules to liquids, making them ideal for sectors such as food, pharmaceuticals, and cosmetics.

Another significant type to consider is the Vertical Bundling Machine, which specializes in grouping products for compact packaging. This type of machine is increasing in demand, particularly in the e-commerce sector, where bundling products can lead to reduced shipping costs and enhanced consumer appeal. Reports indicate that bundling machines can improve efficiency by up to 30% compared to traditional packaging methods. Furthermore, flow wrapping machines provide an alternative for businesses requiring high-speed packaging with minimal material usage, making them suitable for high-volume production lines.

In addition to these types, it's crucial to evaluate features such as automation level, size flexibility, and ease of maintenance. With advancements in technology, modern vertical packaging machines come equipped with smart controls and integration capabilities, enabling real-time monitoring and adjustments to production processes. As businesses strive for efficiency and sustainability, selecting a machine that meets specific needs while being adaptable to changing market demands will be a key factor for long-term success.

Budgeting for Your Vertical Packaging Machine Investment

When considering the purchase of a vertical packaging machine, budgeting is a crucial first step. The cost of these machines can vary significantly based on features, size, and technology. It's essential to evaluate your production needs and how much you are willing to invest. Start by determining your expected production volume and the types of materials you will package. This information will help you narrow down your options and create a realistic budget.

Tips: Before finalizing your budget, consider not just the initial purchase price but also the total cost of ownership, which includes maintenance, training, and potential upgrades. It’s also wise to factor in any hidden costs such as installation and operational changes that may be required to accommodate the new equipment.

Moreover, look into financing options that may help ease the burden on your cash flow. Many suppliers offer financing plans or leasing options that allow businesses to spread out their payments over time. Research grants or financial assistance programs that might be available for purchasing new machinery, as these can significantly offset initial costs.

Tips: Don’t forget to include a contingency in your budget to cover unexpected expenses that may arise during the implementation phase. A well-prepared financial plan not only makes for a smoother purchasing process but also enhances the chances of a successful investment in your vertical packaging machine.

Related Posts

-

Exploring the Benefits of Vertical Packaging Machines for Modern Manufacturing

-

5 Best Horizontal Form Fill Seal Machines for Your Packaging Needs

-

The Ultimate Guide to Choosing the Perfect Seal Machine for Your Packaging Needs

-

Innovative Packaging Solutions for Sustainable Living and Eco Friendly Choices

-

Essential Food Packing Machine Checklist: 10 Key Factors for Optimal Performance

-

How to Choose the Best Pouch Packaging Machine for Your Business Needs