How to Choose the Best Pouch Packaging Machine for Your Business Needs

In today's rapidly evolving packaging industry, businesses face an increasing demand for efficient and versatile solutions, particularly in the form of pouch packaging machines. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2025, with pouch products gaining a substantial share due to their convenience and cost-effectiveness. As companies strive to enhance their product visibility on the shelves and improve consumer experience, choosing the right pouch packaging machine becomes a crucial decision that can significantly impact operational efficiency and market competitiveness.

Industry expert Dr. Sarah Johnson, a leading authority in packaging technology, emphasizes the importance of careful selection in this domain. She states, "The right pouch packaging machine can streamline production processes, reduce waste, and ultimately enhance the overall sustainability of a product line." This highlights the need for businesses to assess their specific requirements, including production volume, pouch format, and sealing technology, before making an investment. With various options available in the market, understanding these dynamics is essential for making informed decisions that align with business objectives and consumer expectations in the dynamic landscape of pouch packaging.

Identifying Your Packaging Requirements for Pouch Machines

When choosing the best pouch packaging machine for your business, it is critical to begin by identifying your specific packaging requirements. Consider the type of products you are packaging—whether they are dry goods, liquids, or powders—as this will significantly influence the technology you need. Each product type has unique characteristics and may require different seal types, film materials, and machine configurations to ensure proper filling and sealing. Conducting a thorough analysis of your product allows you to eliminate options that do not align with your needs.

Additionally, you should assess the volume of production expected from the machine. This involves forecasting daily output and determining how often the machine will be running. A higher production rate may necessitate a more advanced machine with quicker changeover times and user-friendly operation features. Moreover, consider the future growth of your business; choosing a machine that can adapt to increased demands or different packaging types can be a smart investment. Alongside these factors, evaluating your available workspace is essential, as the machine's dimensions and layout will influence its integration into your existing production line.

Understanding the Different Types of Pouch Packaging Machines

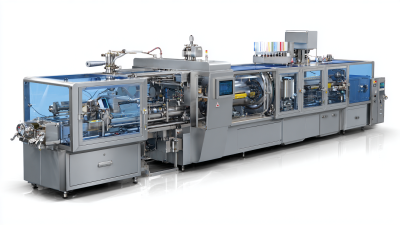

When considering pouch packaging machines for your business, understanding the different types available is crucial. There are primarily three categories: vertical fill-seal machines, horizontal fill-seal machines, and pre-made pouch machines. Vertical fill-seal machines are ideal for products that flow easily, such as powders and granules. They automate the filling and sealing process, which enhances efficiency and reduces labor costs. Typically, these machines are suited for businesses focused on high-speed production and are valued for their compact design.

Horizontal fill-seal machines, on the other hand, are perfect for products that require careful handling, such as delicate food items or liquids. These machines fill and seal pouches in a horizontal position, minimizing product damage and ensuring consistency in fill volume. They often come with customizable features, allowing businesses to adapt to different product shapes and sizes. Lastly, pre-made pouch machines are versatile, as they work with existing pouches, which can be useful for brands looking to maintain a distinct product appearance while also being able to handle various materials and closure types. Each type has its unique benefits, making it essential for businesses to assess their specific needs and production goals before making a choice.

Comparison of Pouch Packaging Machine Types

This chart illustrates the different types of pouch packaging machines based on their market usage percentage. The data reflects the distribution of machine types used in various industries for effective pouch packaging.

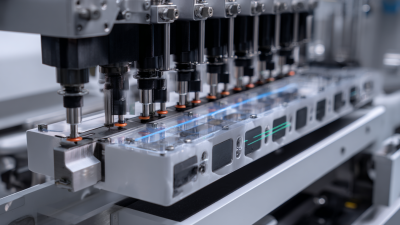

Evaluating Key Features and Specifications of Pouch Machines

When evaluating pouch packaging machines for your business needs, understanding key features and specifications is crucial. One of the first aspects to consider is the machine's speed and efficiency. According to a report by Smithers Pira, the global market for flexible packaging is projected to reach $300 billion by 2025, with an increasing demand for faster production lines. Machines that can handle up to 120 pouches per minute are becoming the industry standard, enabling businesses to meet increasing consumer demands while maintaining profitability.

Another essential factor is the versatility of the pouch packaging machine. Modern models often incorporate a variety of pouch styles, such as stand-up, flat, and zippered pouches, which cater to different product types. A survey by Packaging Strategies indicates that over 60% of consumers prefer flexible packaging due to its convenience and resealability. Therefore, selecting a machine with adjustable features and compatibility with various pouch formats can significantly enhance your product appeal and market reach.

In addition, consider the automation capabilities of the machines. Advanced machines equipped with technologies like servo motors and touch-screen controls allow for precise adjustments and reduced downtime. A study from PMMI reports that companies that invest in automated packaging systems can see a return on investment in less than three years, highlighting the long-term benefits of selecting a high-quality pouch packaging machine tailored to your operations.

Assessing Budgeting and Cost Considerations for Packaging Solutions

When choosing a pouch packaging machine for your business, budgeting and cost considerations play a pivotal role. First and foremost, it is essential to assess your overall packaging budget. This not only involves the initial investment in machinery but also includes ongoing operational costs such as maintenance, material expenses, and labor. Understanding your financial constraints will help narrow down your options and guide you toward machines that deliver the best return on investment.

Next, consider the cost implications of different packaging solutions. While some machines might appear cheaper upfront, they may incur higher costs due to inefficient operation or frequent breakdowns. Evaluate the longevity and reliability of the machinery against its price. Additionally, think about the scalability of your packaging solution. A machine that fits your immediate needs but lacks the capacity for future growth may end up being a costly choice in the long run. Conducting a thorough cost-benefit analysis will ensure that your investment aligns with both current and future business needs.

Researching Supplier Options and After-Sales Support

When selecting a pouch packaging machine, it's crucial to thoroughly research supplier options to ensure you find a reliable partner that meets your business's specific requirements. Start by identifying suppliers with a solid track record in the industry, focusing on their experience and expertise in producing machinery suitable for your product needs. Reading reviews and case studies can provide insight into their capabilities and customer satisfaction levels. Additionally, consider the range of machines they offer, as a diverse product line may indicate adaptability to different packaging needs.

Equally important is evaluating the after-sales support provided by the supplier. Reliable after-sales service can significantly impact your operational efficiency and productivity. Look for suppliers that offer comprehensive support, including installation, training, and maintenance services. It's beneficial to inquire about their customer service response time, availability of spare parts, and warranty terms. Ensuring that your chosen supplier prioritizes after-sales support will help you mitigate downtime and maintain your packaging processes seamlessly, ultimately enhancing your business's overall performance.

Related Posts

-

10 Essential Tips for Choosing the Best Pouching Machine for Your Business Needs

-

How to Choose the Best Pouch Packaging Machine for Your Business Needs

-

Innovative Pouching Machine Designs Transforming Packaging Solutions

-

Discover the Future of Packaging: How Horizontal Form Fill Seal Machines Revolutionize Efficiency

-

Top 10 Pharmaceutical Filling Machines: Boost Efficiency by 30% in 2023

-

20 Best Innovations in Wrapping Machines You Need to Know