10 Essential Tips for Choosing the Best Pouching Machine for Your Business Needs

In today's rapidly evolving packaging landscape, selecting the right pouching machine is crucial for businesses aiming to enhance efficiency and meet consumer demands. According to a report by Grand View Research, the global pouches market is expected to reach USD 28.57 billion by 2025, growing at a CAGR of 5.4%. This growth is driven by the increasing preference for convenient, lightweight packaging solutions that pouches offer, making the choice of an appropriate pouching machine more critical than ever.

Moreover, in a study conducted by Smithers Pira, it was noted that flexible packaging, including pouches, accounted for approximately 25% of the total packaging market share in recent years, highlighting the rising trend among manufacturers. Therefore, investing in a pouching machine that aligns with your specific production requirements can significantly impact not only your operational efficiency but also your market competitiveness. This article outlines ten essential tips for choosing the best pouching machine tailored to your business needs, ensuring you remain at the forefront of this dynamic industry.

Understanding Different Types of Pouching Machines: A Comparative Analysis

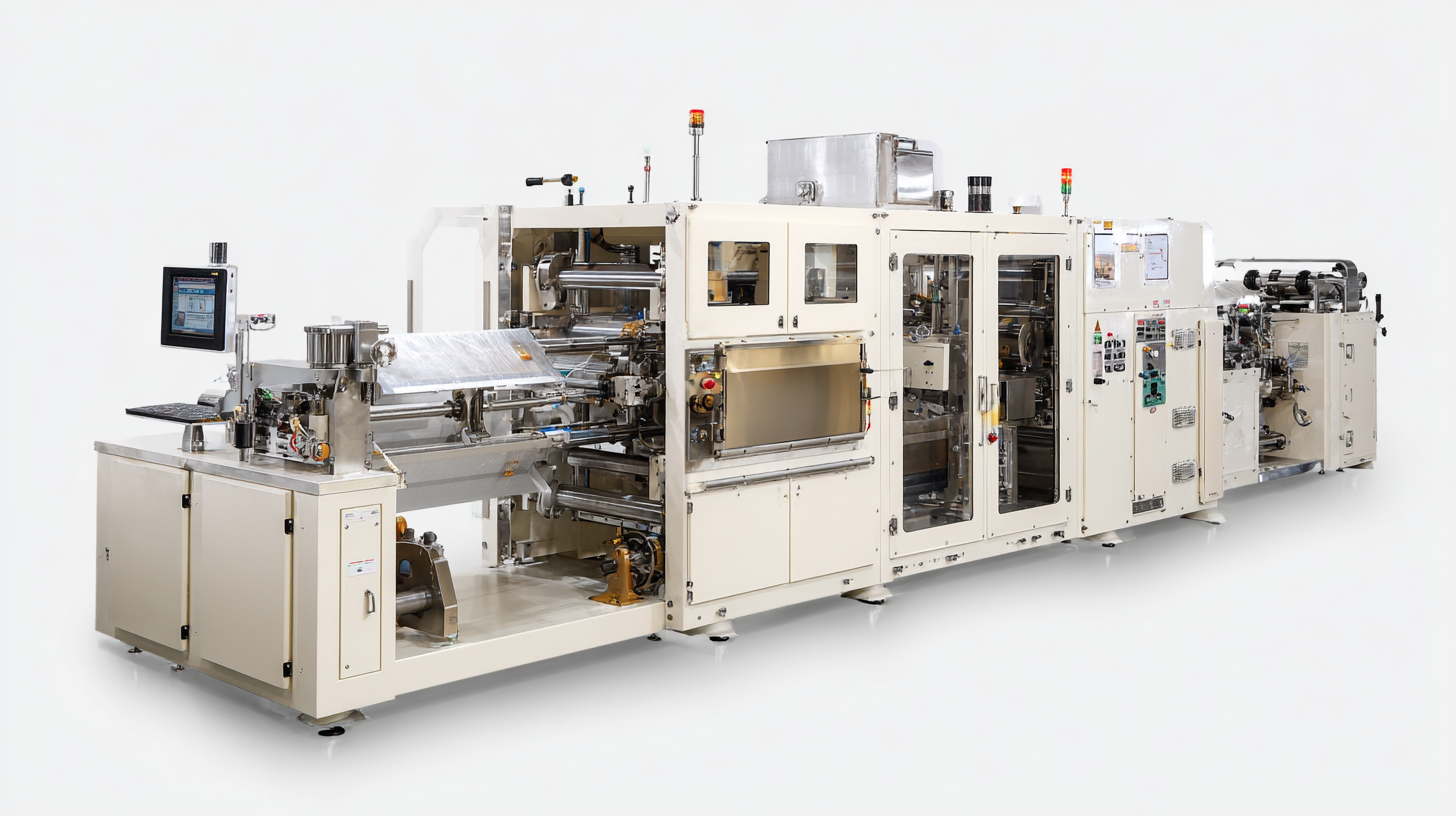

When selecting a pouching machine for your business, it's crucial to understand the differences among various types available in the market. The three predominant types—vertical form fill seal (VFFS), horizontal form fill seal (HFFS), and pre-made pouch filling machines—each offer distinct advantages suited to specific production needs. According to a recent report from the Flexible Packaging Association, the flexible packaging market is expected to grow by 4.5% annually, indicating a rising demand for efficient and versatile pouching solutions.

Tip 1: Assess your product type and packaging requirements. VFFS machines are ideal for granular products, while HFFS is better for larger, flat items. Pre-made pouch filling machines can cater to a broader range of products, particularly liquids and powders, allowing for more customization in packaging designs.

Tip 2: Consider the speed and efficiency of the machine. Machines capable of filling and sealing up to 150 pouches per minute are available, which can significantly enhance production rates. According to industry analyses, investing in a higher-speed machine can reduce operational costs and improve overall profit margins.

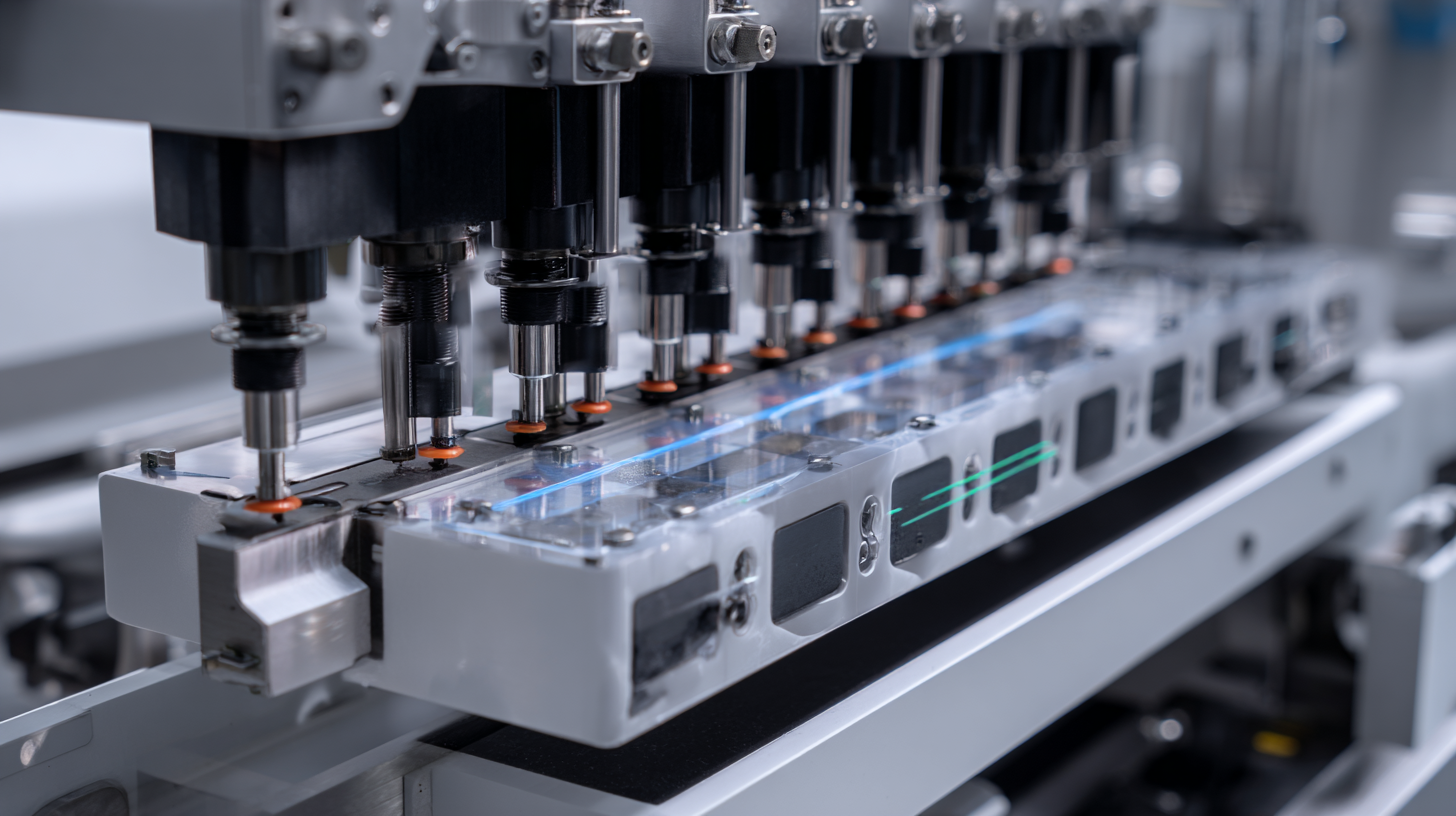

Tip 3: Evaluate the machine’s compatibility with automation systems. A report by PMMI notes that over 75% of manufacturers are prioritizing automation to streamline their processes. Integrating advanced technology can optimize workflow and reduce labor costs, making a pouching machine a strategic investment for future growth.

Evaluating Production Speed and Efficiency Metrics for Pouching Machines

When selecting a pouching machine for your business, evaluating production speed and efficiency metrics is crucial. According to a recent report by the Packaging Machinery Manufacturers Institute (PMMI), the average packaging line operates at about 75% of its potential speed due to inefficiencies. Understanding how pouching machines can perform under different operational scenarios is essential. Machines that can achieve speeds of 60-100 pouches per minute, depending on the product type and pouch size, can significantly enhance throughput. By analyzing cycle times and the ability to switch between pouch sizes quickly, businesses can optimize their production processes.

In addition to speed, evaluating the overall equipment effectiveness (OEE) provides a comprehensive view of a pouching machine's efficiency. The OEE metric is comprised of availability, performance, and quality rates, which collectively indicate how well a machine operates compared to its maximum capacity. A recent study indicated that machines with a higher OEE of 85% or more not only reduce production costs but also improve lead times. Therefore, investing time to assess these metrics before purchasing can lead to more informed decisions and enhance productivity in long-term operations.

Production Speed and Efficiency Metrics for Pouching Machines

Assessing Material Compatibility: Choosing the Right Machine for Your Packaging Needs

When choosing a pouching machine for your business, particularly in the medical device sector, assessing material compatibility is crucial. Each medical device has specific packaging requirements that adhere to stringent regulatory standards. Using the correct materials not only protects the products but also ensures compliance with safety regulations. For instance, the choice of film and seals can affect the sterility and integrity of the packaged device. Therefore, manufacturers need to consider the compatibility of their pouching materials with the devices being packaged, as well as the environmental conditions to which they will be subjected.

In addition to material compatibility, businesses must evaluate the type of pouches and sealing techniques that best suit their operational processes. Medical device packaging often involves complex considerations, such as the selection of disposable gloves that must be used in sterile environments. Understanding these dynamics can help manufacturers streamline their processes while ensuring that their packaging meets both functional and regulatory demands. By critically assessing these factors, businesses can choose the right pouching machine that not only caters to their packaging needs but also enhances overall efficiency and compliance.

Key Features to Look For in Pouching Machines: Automation vs. Manual Options

When selecting a pouching machine for your business, understanding the differences between automation and manual options is crucial. Automated pouching machines streamline production with high-speed operations, reducing labor costs and minimizing human error. These machines are ideal for businesses looking to scale up production or meet high-volume demands. Features to look for include programmable settings, multiple pouch styles, and integration with existing production lines. The convenience of automation can lead to significant efficiency gains, making it a worthy investment for growing businesses.

On the other hand, manual pouching machines offer greater flexibility and control, making them suitable for smaller operations or businesses that require custom packaging solutions. These options typically have a lower initial investment, allowing businesses to test different configurations before committing to automation. Key aspects to consider in manual machines include ease of use, maintenance requirements, and the variety of pouch sizes they can produce. Ultimately, the choice between automation and manual options will depend on your business's specific needs, production volume, and budget constraints.

10 Essential Tips for Choosing the Best Pouching Machine for Your Business Needs - Key Features to Look For in Pouching Machines: Automation vs. Manual Options

| Feature | Automation Option | Manual Option | Best For |

|---|---|---|---|

| Speed | High-speed operation, ideal for large-scale production | Slower, suitable for smaller batches | High-volume manufacturers |

| Flexibility | Covers a wide range of pouch sizes and styles | Limited to specific sizes and shapes | Businesses with diverse packaging needs |

| Ease of Use | User-friendly interface with automation | Requires manual setup and operation knowledge | Users with varying levels of experience |

| Maintenance | Generally requires specialized maintenance | Easier to maintain with basic tools | Small businesses with limited resources |

| Cost | Higher initial investment, but cost-effective in volume | Lower upfront cost but less efficient | Startups and low-budget operations |

Budgeting for Your Pouching Machine: Initial Investment vs. Long-Term ROI

When considering the purchase of a pouching machine, budgeting is critical to ensure that you're not just focusing on initial costs but also on long-term return on investment (ROI). According to a report by Smithers Pira, the flexible packaging market is projected to reach $300 billion by 2024, making efficiency improvements through suitable machinery increasingly vital. While the upfront cost of quality pouching machines can range from $20,000 to $150,000 depending on size and automation level, the long-term savings in labor and material waste are significant.

One essential tip is to assess the total cost of ownership (TCO) rather than just the purchase price. This includes maintenance, energy consumption, and the potential cost of downtime. Another important consideration is scalability; choose a machine that can adapt to changing business needs without requiring a complete overhaul in the near future. This foresight can substantially enhance your ROI as the business grows, aligning production capabilities with market demand efficiently.

Incorporating automated features can also contribute to a better long-term ROI. Machines with advanced technology often reduce labor costs and improve throughput. According to a survey by Packaging Machinery Manufacturers Institute (PMMI), 67% of companies that invested in automation experienced an ROI within three years. Planning for these factors will ensure that the chosen pouching machine not only fits your budget but also serves your business well into the future.

Related Posts

-

How to Choose the Best Pouch Packaging Machine for Your Business Needs

-

Innovative Pouching Machine Designs Transforming Packaging Solutions

-

Exploring Industry Growth: Vertical Form Fill Seal Machines at the 138th Canton Fair 2025

-

Unlocking Efficiency and Profitability with Powder Packaging Machines for Global Suppliers

-

Exploring the Benefits of Vertical Packaging Machines for Modern Manufacturing

-

Essential Food Packing Machine Checklist: 10 Key Factors for Optimal Performance