How to Optimize Your Production Line Using Stick Pack Machines for Maximum Efficiency

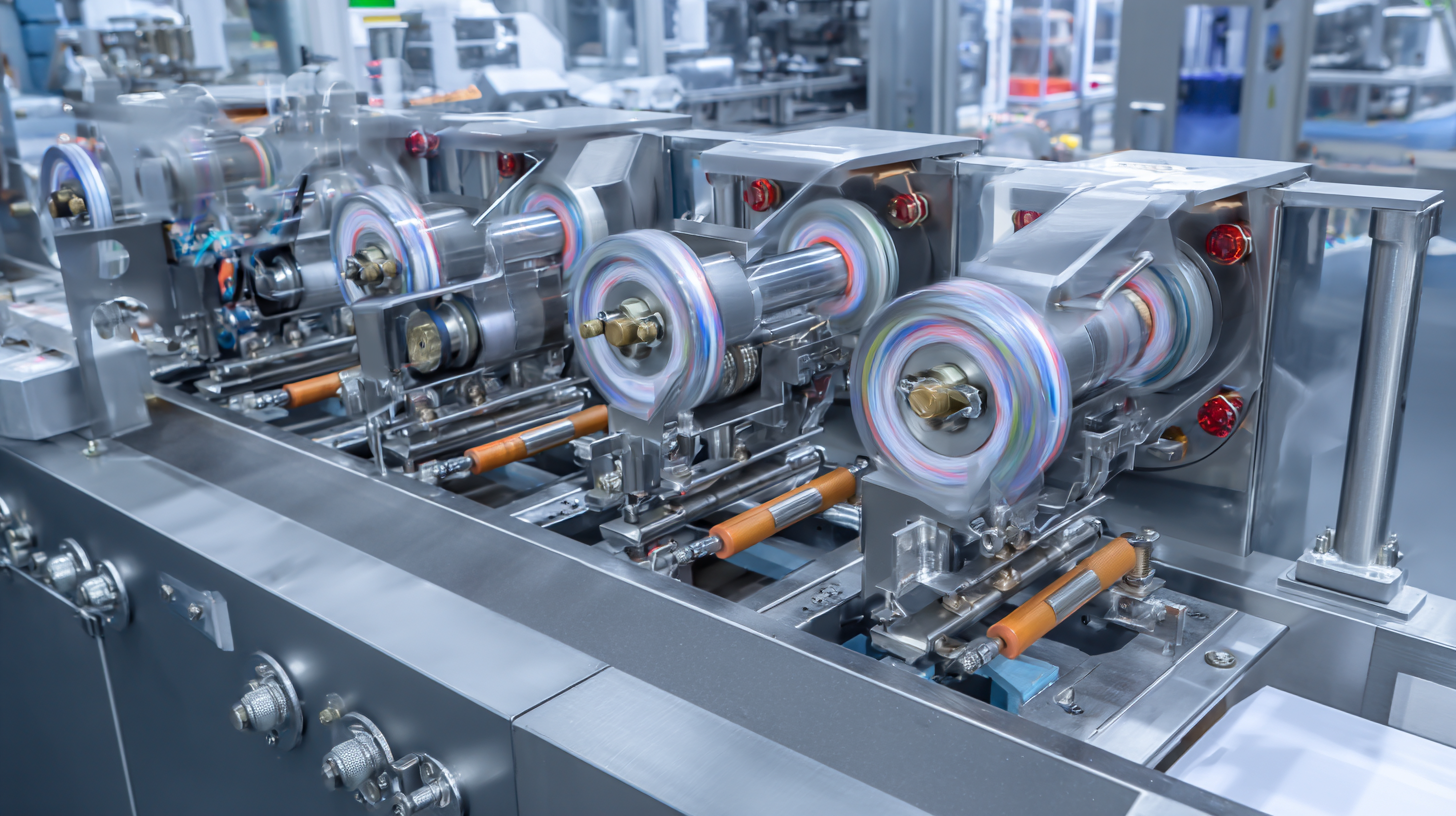

In today's highly competitive manufacturing landscape, optimizing production lines has become crucial for achieving maximum efficiency and profitability. A pivotal element in this optimization process is the implementation of stick pack machines, which have revolutionized the packaging industry by providing a streamlined solution for high-speed and flexible packaging. According to a recent report by MarketsandMarkets, the stick pack packaging market is expected to grow from USD 3.62 billion in 2021 to USD 5.22 billion by 2026, reflecting a CAGR of 7.5%. This significant growth underscores the increasing demand for stick pack machines as manufacturers seek to enhance their operational efficiency and meet consumer preferences for convenience and portability. By leveraging advanced stick pack machines, companies can not only reduce production times but also minimize material waste, resulting in a more sustainable and cost-effective packaging process.

Selecting the Right Stick Pack Machine for Your Production Needs

When selecting the right stick pack machine for your production needs, it’s essential to consider several key factors that can greatly affect your operation's efficiency. Start by assessing the type of product you will be packaging. Different machines cater to various materials, whether you are dealing with powders, granules, or liquids. Understanding the specific requirements of your product will help narrow down your options.

**Tip:** Research the machine's compatibility with your product format and ensure it can handle the necessary fill weights and sizes.

Speed and output capacity are also crucial elements to evaluate. Look for machines that not only meet your current production demands but also allow room for future growth. A machine with adjustable speeds can provide flexibility, enabling you to scale up production as needed without compromising efficiency.

**Tip:** Consider investing in a machine that features automation capabilities, as this can significantly reduce labor costs and enhance overall productivity.

Lastly, do not overlook the importance of after-sales support and maintenance services. A reliable manufacturer should offer comprehensive support, ensuring minimal downtime for your production line.

**Tip:** Check customer reviews and testimonials to gauge the level of service provided by the manufacturer before making a decision.

How to Optimize Your Production Line Using Stick Pack Machines for Maximum Efficiency

| Feature | Description | Impact on Production | Efficiency Increase (%) |

|---|---|---|---|

| Speed of Production | Can operate up to 150 packs per minute | Reduces time taken per unit | 20% |

| Changeover Time | Less than 15 minutes for format changes | Minimizes downtime during product switch | 15% |

| Footprint | Compact design to save space | Allows better layout of production facilities | 10% |

| Versatility | Can handle a variety of product sizes | Increases the range of products produced | 25% |

| Automation | Equipped with advanced control systems | Enhances precision and reduces labor costs | 30% |

Key Features to Look for in High-Efficiency Stick Pack Machines

When selecting high-efficiency stick pack machines for your production line, there are several key features that can significantly enhance productivity.

Firstly, consider the machine's speed and output capacity. According to a report by the International Packaging Association, modern stick pack machines can achieve speeds of up to 300 packs per minute.

This level of efficiency is crucial for meeting high demand and reducing bottlenecks in the production process, which can ultimately lead to increased profitability.

Additionally, versatility in packaging formats is essential. High-efficiency stick pack machines should be able to handle a variety of products, ranging from powders to granules and liquids.

Research indicates that manufacturers with flexible packaging systems are 20% more productive due to their ability to switch between different packaging types with minimal downtime.

Furthermore, look for machines that feature advanced automation technologies. Features such as automatic feeding systems and smart sensors not only enhance reliability but also ensure consistent packaging quality, reducing waste and improving overall operational efficiency.

Best Practices for Integrating Stick Pack Machines into Your Workflow

Integrating stick pack machines into your production workflow can significantly enhance efficiency and streamline operations. According to a recent report by Smithers Pira, the flexible packaging market is projected to grow to $410 billion by 2027, driven largely by innovations like stick packing. These machines allow for precise dosing and packaging of products into single-serving formats, which caters to consumer demand for convenience and portion control. Implementing stick pack machines can reduce labor costs by up to 30% when compared to traditional packaging methods, making them a worthwhile investment.

To effectively incorporate stick pack machines, it's essential to train your workforce in their operation and maintenance, as well as to adapt your existing production layout for optimal workflow. A lean layout not only minimizes movement and potential bottlenecks but also maximizes productivity. A study by the International Society of Automation indicates that companies adopting these best practices can increase their production efficiency by at least 25%. Moreover, evaluating your supply chain to ensure that ingredients or products fed into the stick pack machines are readily accessible can further enhance throughput, making your entire operation more effective in meeting market demands.

Techniques for Streamlining Maintenance and Reducing Downtime

In today’s competitive manufacturing environment, optimizing production line efficiency is crucial for maintaining profitability. Stick pack machines, known for their precision and versatility, can significantly streamline operations. However, focusing on maintenance strategies is essential to reduce downtime and ensure these machines operate at peak performance. According to a report by the National Institute of Standards and Technology, effective maintenance can decrease equipment failures by up to 30%, highlighting the importance of a well-structured maintenance program.

Implementing a proactive maintenance schedule is one of the key techniques. Regular inspections and timely replacement of worn-out components not only extend the lifespan of stick pack machines but also prevent unexpected breakdowns. The Manufacturing Performance Institute notes that organizations that adopt predictive maintenance strategies can achieve a 12% reduction in maintenance costs and a 20% increase in productivity. By utilizing data analytics and sensor technologies, manufacturers can foresee potential issues and address them before they escalate, significantly minimizing unplanned downtime.

Additionally, training staff on maintenance best practices is vital. A well-informed workforce can identify early signs of wear and detect issues promptly, ultimately contributing to the overall efficiency of the production line. Research from the Lean Enterprise Institute indicates that companies that invest in employee training report a 35% reduction in equipment downtime. By focusing on maintenance and employee education, manufacturers can maximize the potential of stick pack machines and enhance production efficiency.

Analyzing Production Data to Enhance Workflow and Efficiency

Analyzing production data is essential for enhancing workflow and efficiency in any production line. By integrating advanced data analytics techniques, manufacturers can identify bottlenecks, minimize downtime, and optimize machine performance. In the context of stick pack machines, utilizing real-time data can help assess various metrics such as speed, output, and quality of product packaging. These insights not only reveal the current status of the production line but also guide future improvements.

**Tips for Optimizing Your Production Line:**

1. Implementing data collection systems that automatically track performance metrics will provide actionable insights and help maintain efficiency.

2. Regularly review and analyze production data to identify patterns that may indicate issues in the workflow, allowing for timely interventions.

3. Invest in training employees on data analysis tools to empower them to contribute to continuous improvement processes.

Additionally, incorporating flexible workflows in data analysis allows for quicker adaptation to changes in production requirements. Leveraging interactive data visualization techniques enables non-technical users to engage with the data, leading to more informed decision-making. By enhancing the ability to interpret production data, manufacturers can streamline operations, ultimately driving productivity and maintaining a competitive edge.

Production Line Efficiency with Stick Pack Machines

Related Posts

-

How to Choose the Right Form Fill and Seal Machine for Your Packaging Needs

-

The Ultimate Guide to Comparing Packaging Automation Solutions for Global Buyers

-

Essential Food Packing Machine Checklist: 10 Key Factors for Optimal Performance

-

7 Unique Benefits of Using a Pharmaceutical Filling Machine for Your Production流程

-

Unlocking Efficiency and Profitability with Powder Packaging Machines for Global Suppliers

-

Innovative Pouching Machine Designs Transforming Packaging Solutions